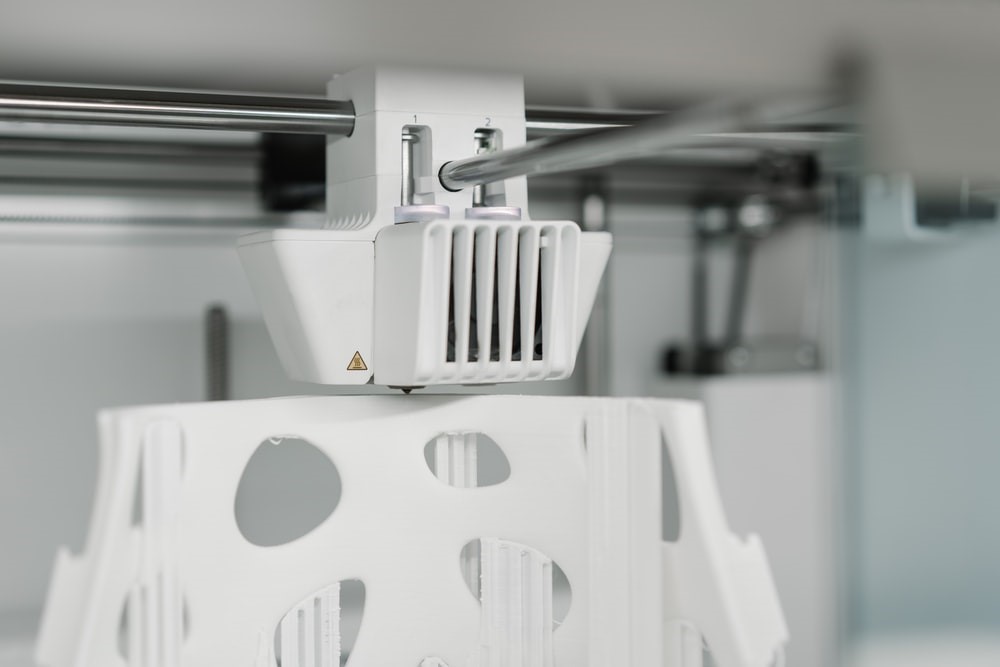

When developing a product prototype, it is prudent to consider the best tools and processes for completing your design. Subtractive manufacturing (CNC machine parts), injection moulding (designed to pre-produce prototypes), and additive manufacturing (3D printing) are the three primary methods for producing prototypes.

Understanding the differences between these three types of product development methods is critical for selecting the right technology for your project and determining whether 3D printing is the best option.

The advantages of 3D printing technology

Many businesses have adopted 3D printing. Others intend to use the technology to replace traditional subtractive manufacturing methods. According to recent research, more than 70% of manufacturers have now adopted 3D printing. Furthermore, more than half of respondents anticipate that 3D printing technology will be used for high-volume product development, and about 22 percent believe that its effects on supply chains will be even more disruptive.

The use of 3D printing technology can provide numerous advantages to both individuals and businesses. Here are ten significant benefits of 3D printing technology.

Increased productivity

3D printing is faster than traditional manufacturing methods like injection moulding and subtractive manufacturing. Consider the difference between the speed of a sports car and the speed of a horse and a cart. Both will arrive at their destination, but the time difference is enormous. 3D printing quickly tests ideas and designs from prototype to final product.

Faster design and prototyping mean more time to iterate the prototype and find product market fit ahead of competitors. Production through 3D printing takes only a few hours. On the other hand, testing ideas and designs with traditional manufacturing methods can take days, if not weeks.

Easy to invest in

Although 3D printing has been around for decades, it did not really take off until 2010. As competition in the 3D printing space increased, consumers’ access to easier-to-use software and hardware has increased. As a result, learning the technology has never been easier, and you can incorporate it into your production cycle in a matter of days.

Improved quality

Traditional manufacturing methods are prone to producing poor designs and, as a result, poor-quality prototypes. Consider the following scenario: someone wants to bake a cake by combining all the ingredients, mixing them together, and placing them in the oven to bake. If the ingredients were not thoroughly combined, the cake may contain air bubbles or fail to cook thoroughly. That is how some subtractive or injection moulds can be. Quality cannot be guaranteed 100 percent of the time. However, 3D printing allows for object assembly in stages, resulting in improved designs and, eventually, higher quality objects.

Tangible product design and testing

A prototype’s feel cannot be compared to seeing it on a screen or virtually. 3D printing makes it possible to physically test the product prototype by touching and feeling it to find flaws in the design. If a problem is discovered, you can modify the CAD file and print a new version the following day.

Value for money

The amount of money spent on developing a prototype is heavily influenced by labour costs. Traditional prototyping methods, like production runs and injection moulds, are expensive because they require a lot of human labour. Labour costs are also extremely high in conventional subtractive manufacturing. To handle production, you’ll need skilled machine operators and technicians. You must also pay these labourers and use costly machinery. However, with 3D printing, labour can be as simple as one person issuing a print command, making it exceptionally cost-effective.

Design flexibility and customisation

Traditional manufacturing techniques can produce millions of identical items. It creates the same dull and boring designs with little room for improvement. It is extremely difficult to make each design unique using these techniques.

3D printing allows for infinite personalisation, making it much easier to accommodate customer requests for personal touches. The only limitation is your imagination. For example, you can create a dental crown that is precisely engineered to fit in someone’s mouth. This reduces the number of patient visits to ensure they have a properly fitting crown.

Infinite geometry and shapes

Moulds and cutting technologies are used in traditional manufacturing to create the desired shapes. With this technology, designing geometrically complex shapes can be difficult and costly. However, this challenge is easily met by 3D printing, and there isn’t much the technology can’t do with the right support material.

Various raw materials

Product designers must carefully calculate their steps when it comes to materials to use with either subtractive or injection mould manufacturing. Blending raw materials is not supported by mass manufacturing because it is costly. Moreover, combining chemical and physical elements is difficult. However, glass, metal, paper, ceramics, biomaterials, silver, and other materials are easily accommodated by 3D printing.

Reduced waste

CNC cutting and injection moulding both waste a lot of resources. Both involve material removal from solid blocks. In contrast, 3D printing only uses the material required to create a prototype part – no more, no less. Furthermore, reusing the materials from a 3D print is a simple process. As a result, additive manufacturing produces very little waste while saving a significant amount of money.

Risk mitigation

A good designer understands that proper design verification is critical before investing in an expensive moulding tool when it comes to product manufacturing. 3D printing technology allows product designers to test prototypes before making significant manufacturing investments that can sometimes be disastrous.

Contact MeiMag Electronics for more details

With 3D printing, you can turn a concept into a reality faster than you can imagine. Products are manufactured quickly and cheaply. Without a doubt, technology will continue to transform every industry, altering the way we work and live in the future.

Companies like MeiMag Electronics can assist you in making the best 3D printer choice for your needs. We can offer the best quality products and services at competitive pricing because we have been in the industry for over 23 years and have built strong relationships with our suppliers. So get in touch with us today.